Ingangsdatum: 01-01-2005

Geldig tot en met: 31-12-2005

PreambleIt has long been recognised that the only way of

ensuring that the condition of a ship's structure is maintained to conform with the

applicable requirements is for all its components to be surveyed on a regular basis

throughout their operational life so as to ensure that they are free from damage such

as cracks, buckling or deformation due to corrosion, overloading or contact damage and

that thickness diminution is within established limits. The provision of suitable

means of access to the hull structure for the purpose of carrying out overall and

close-up surveys and inspections is essential and such means should be considered and

provided for at the ship design stage.

Ships

should be designed and built with due consideration as to how they will be surveyed by

flag State inspectors and classification society surveyors during their in-service

life and how the crew will be able to monitor the condition of the ship. Without

adequate access, the structural condition of the ship can deteriorate undetected and

major structural failure can arise. A comprehensive approach to design and maintenance

is required to cover the whole projected life of the ship.

In order to address this issue, the Organization has developed these

Technical provisions for means of access for inspections, intended to facilitate

close-up inspections and thickness measurements of the ship's structure referred to in

SOLAS regulation II-1/3-6 on Access to and within spaces in the cargo area of oil

tankers and bulk carriers.

DefinitionsTerms used in the Technical provisions have the

same meaning as those defined in the 1974 SOLAS Convention, as amended, and in

resolution A.744(18), as amended.

Technical

provisions1 Structural members subject to the

close-up inspections and thickness measurements of the ship's structure referred to in

SOLAS regulation II-1/3-6, except those in double bottom spaces, shall be provided

with a permanent means of access to the extent as specified in table 1 and table 2, as

applicable. For oil tankers and wing ballast tanks of ore carriers, rafting may be

used in addition to the specified permanent means of access, provided that the

structure allows for its safe and effective use.

2 Elevated passageways, where fitted, shall have a minimum width of 600 mm

and be provided with toe boards not less than 150 mm high and guard rails over both

sides of their entire length. Sloping structure providing part of the access shall be

of a non-skid construction. Guard rails shall be 1,000 mm in height and consist of a

rail and intermediate bar 500 mm in height and of substantial construction. Stanchions

shall be not more than 3 m apart.

3 Access

to elevated passageways and vertical openings from the ship's bottom shall be provided

by means of easily accessible passageways, ladders or treads. Treads shall be provided

with lateral support for the foot. Where the rungs of ladders are fitted against a

vertical surface, the distance from the centre of the rungs to the surface shall be at

least 150 mm. Where vertical manholes are fitted higher than 600 mm above the walking

level, access shall be facilitated by means of treads and hand grips with platform

landings on both sides.

4 Tunnels passing

through cargo holds shall be equipped with ladders or steps at each end of the hold so

that personnel may easily cross such tunnels.

5 Permanent ladders, except for vertical ladders, which are fitted on

vertical structures for close-up inspection or thickness measurement, shall be

inclined at an angle of less than 70º. There shall be no obstructions within 750 mm of

the face of the inclined ladder, except that in way of an opening this clearance may

be reduced to 600 mm. The flights of ladders shall not be more than 9 m in actual

length. Resting platforms of adequate dimensions shall be provided. Ladders and

handrails shall be constructed of steel or equivalent material of adequate strength

and stiffness and securely attached to the tank structure by stays. The method of

support and length of stay shall be such that vibration is reduced to a practical

minimum. In cargo holds, ladders shall be designed and arranged so that the risk of

damage from cargo handling gear is minimized.

6 The width of ladders between stringers shall not be less than 400 mm. The

treads shall be equally spaced at a distance apart, measured vertically, of between

250 mm and 300 mm. When steel is used, the treads shall be formed of two square bars

of not less that 22 mm by 22 mm in section, fitted to form a horizontal step with the

edges pointing upward. The treads shall be carried through the side stringers and

attached thereto by double continuous welding. All sloping ladders shall be provided

with handrails of substantial construction on both sides, fitted at a convenient

distance above the treads.

7 No

free-standing portable ladder shall be more than 5 m long.

8 Portable ladders more than 5 m long may only be utilized if

fitted with a remotely controlled mechanical device to secure the upper end of the

ladder.

9 Movable means of access includes

such devices as:

.1 hydraulic arm fitted

with a stable base and with local control at the safety cage. The operational

conditions should be in accordance with applicable safety requirements of the

manufacturer; and

.2 wire lift platform.

10 For bulk carriers, access ladders to a

cargo hold shall be:

.1 where the vertical

distance between the upper surface of adjacent decks or between deck and the bottom of

the cargo space is not more than 6 m, either a vertical ladder or an inclined ladder;

and

.2 where the vertical distance between

the upper surface of adjacent decks or between deck and the bottom of the cargo space

is more than 6 m, an inclined ladder or ladders, except the uppermost 2.5 m of a cargo

space measured clear of overhead obstructions and the lowest 6 m may have vertical

ladders, provided that the vertical extent of the inclined ladder or ladders

connecting the vertical ladders is not less than 2.5 m.

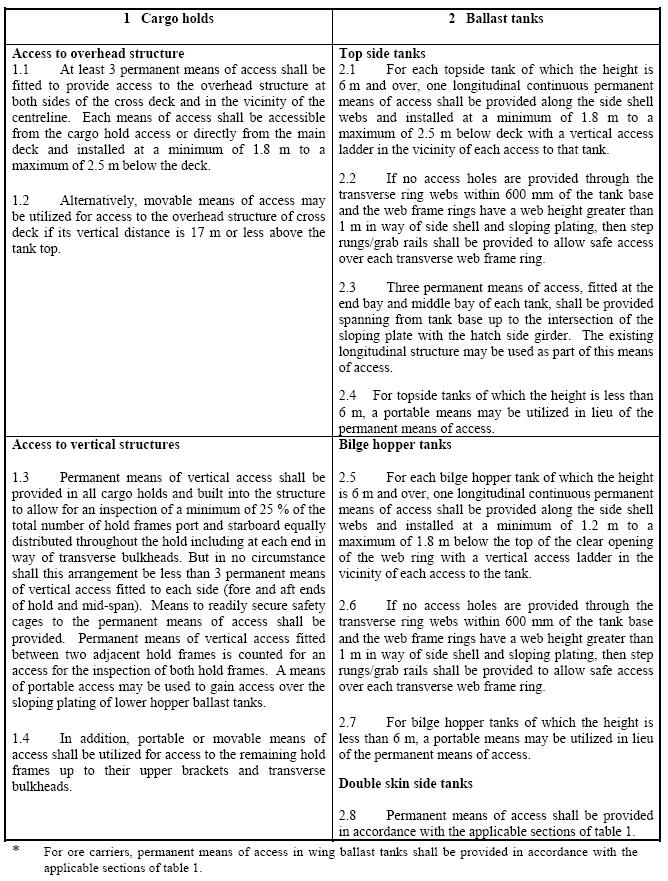

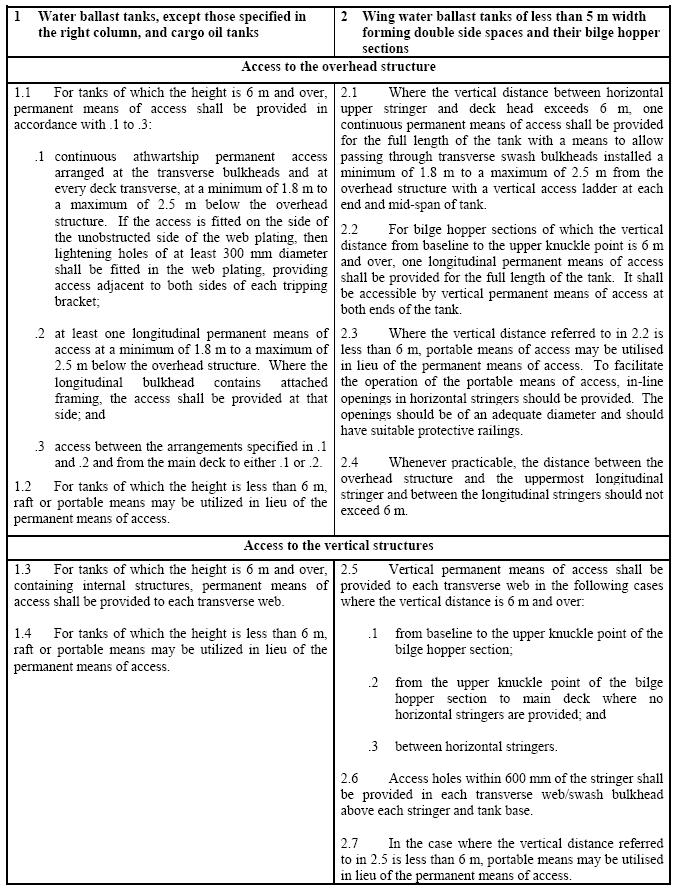

TABLE 1 Means of access for oil tankers TABLE 2 Means of access for bulk carriers*

TABLE 2 Means of access for bulk carriers*