Additional tests applicable only to liferafts with extended service intervals

5.4.1 Recording of humidity

The humidity behind the protective barrier of the four liferafts in the test sequence and in the operationally packed conditions should be measured and recorded using the procedure described in 5.4.4.3. The humidity should not exceed a relative humidity corresponding to 65% rH at 20ºC. If drying agent is used to bring the humidity down to the acceptable level, its effect should be removed for the remainder of the test. No underpressure should be induced behind the protective barrier before or during the prototype test sequence.

5.4.2 Vibration/shock test

The liferafts in the operationally packed conditions should be subjected to a vibration and shock test.

- Testing machinery

The impacts specified under test procedures should be capable of being obtained for the liferafts at the base of the mounting.

- Mounting of the liferaft

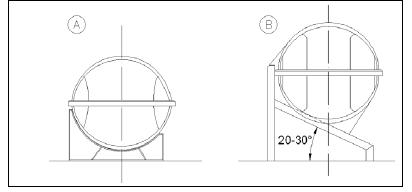

Mounting on the test machine should simulate the mounting on board a ship. Thus, the liferaft is fastened to the vibration table by its cradle and in its normal position, oriented normally with respect to gravity in all three axes. Figure 1 shows types of representative mounting arrangements, where type B may be used to cover most types of container configurations, while type A is generally applicable for liferafts with a capacity of up to 16 persons.

- Test procedures

The test is defined as a random endurance vibration test.

Reference: IEC 60068-2-64, Test Fh: Vibration, broadband random (digital control).

| Frequency range: |

2-100 Hz |

|

| Acceleration spectral: |

2-13 Hz |

12 dB/octave |

| Density |

13-100 Hz |

0.011 g2/Hz |

| Total RMS level: |

1 g |

|

| Duration: |

180 minutes per axis |

|

| Number of axes: |

3, mutually perpendicular |

|

5.4.3 Replacement of items with expiry date

If the service interval approval applied for exceeds the lifetime of dated items in the liferaft, it should be demonstrated that expired items can be replaced without compromising the protective barrier. This test should be carried out after the vibration test, and compliance should be proven through the damp heat cyclic test.

5.4.4 Damp heat cyclic test

Following the vibration test, the liferafts, still in the operationally packed condition, should be exposed to a damp heat cyclic test in accordance with IEC 60068-2-30.

- The test should consist of four cycles of 24 hours’ duration and the lower and upper temperature used should be 25ºC and 65ºC, respectively.

- The variant for the temperature-fall period should be variant 1 shown in figure 2a of IEC 60068-2-30.

- After the completion of the test, the liferaft should be removed from the test chamber and allowed to rest for 24 h. The humidity level behind the protective barrier should then be measured, using a procedure which will prevent air from the surroundings from affecting the test results. The relative humidity at a temperature corresponding to 20ºC should not exceed 65% rH.

5.4.5 Access to lifting hook (applicable to davit-launched liferafts only)

It should be established by a test that there is easy access to the lifting hook or bridle on davit-launched liferafts after the vibration test has been carried out.

5.4.6 Drop test

Following the test in 5.4.4 (and 5.4.5 as applicable), two liferafts should subsequently be subjected to the drop test described in paragraph 5.1 of Part 1 of the Revised recommendation on testing of life saving appliances (resolution MSC.81(70)).

5.4.7 Cold inflation test

Following the damp heat cyclic test, two liferafts should be subjected to a cold inflation test in accordance with paragraph 5.17.5 of Part 1 of the Revised recommendation (resolution MSC.81 70)).

5.4.8 Pressure test

The liferafts should be subjected to the test described in paragraphs 5.17.7 and 5.17.8 of Part 1 of the Revised recommendation (resolution MSC.81(70)). The liferafts should be subjected to the test described in paragraphs 5.1.5 and 5.1.6 of Part 2 of the Revised recommendation (resolution MSC.81(70)) in order to reveal any leaks caused by previous tests.

5.4.9 Floor seam test

The liferafts should be subjected to the floor seam test described in paragraph 5.9 of the Recommendation on conditions for the approval of servicing stations for inflatable liferaft (resolution A.761(18), as amended by resolution MSC.55(66)).

5.4.10 Detailed inspection

Liferafts which have been subjected to the above specified tests, and have been found to comply with the acceptance criteria, should then be subjected to a thorough visual inspection in order to reveal any damage, wearing or chafing which may have been imposed by the previous tests.

*

Examples:

If approval is applied for liferafts in the range of 6-8 persons and in the range of 21-39 persons, two liferafts from the range 5.2.1 and two liferafts from the range 5.2.3 should be selected for a test sequence. If approval is applied for a 10-person liferaft only, four liferafts should be selected from range 5.2.2, which could be four 10-person liferafts.

If approval is applied for liferafts from three ranges, the collection of liferafts for the test sequences should be two liferafts from the first two ranges and four liferafts from the third range.