No. 24 - Ban on the use of Asbestos on board ships

Instruction to Ship owners , Shipping companies and Recognized Organizations (RO’s)1

Registered under: Instruction to RO's No. 24 Ban on the use of Asbestos on board ships

( Date Entry Into Force: 01-12-2011)

1 Revised version nr.3 dated July 2013

Introduction

Since the 1st of July 2002, the installation of materials that contain asbestos has, under SOLAS Ch. II-1,Regulation 3.5.2, been prohibited for all ships, except for:

vanes used in rotary vane compressors and rotary vane vacuum pumps;

watertight joints and linings used for the circulation of fluids when, at high temperature (in excess of 350 °c) or pressure (in excess of 7 x 106 Pa), there is a risk of fire, corrosion or toxicity; and supple and flexible thermal insulation assemblies used for temperatures above 1000 °c.

From the 1st of January 2011, any installation of materials that contain asbestos will, under SOLAS Ch. II-1,Regulation 3.5.2, be prohibited, for all ships without exceptions.

Despite the clear and unambiguous prohibition of asbestos containing materials (ACMs), asbestos is still found on various locations on board ships. During inspections, asbestos has been found in such places as fire blankets, joints and insulation materials, types of sealants, friction material for brakes, wall and ceiling coverings, cords, remnants, electric fuses, etc., despite of an asbestos free declaration or certificate issued by the shipyard. Moreover, ships that initially were free of asbestos appear to have asbestos on board as a result of repairs at shipyards and/or of purchasing spare parts at a later stage. During a limited inspection campaign in the Netherlands ports on board 12 foreign flagged vessels, delivered after the 1st of july 2002, in the last quarter of 2012, asbestos containing material was found onboard 11 vessels.

The Netherlands submitted a proposal to the IMO, which finally resulted in the MSC.1/Circ.1374, Information on prohibiting the use of asbestos on board ships and introduced a paper in the Paris Memorandum of Understanding on Port State Control ( PMoU), which resulted in a guideline, in order to increase the awareness on the use of asbestos on board ships.

The Netherlands Shipping Inspectorate is of the opinion that this instruction, “Ban on the use of Asbestos on board ships” is a temporary solution to reduce the asbestos containing materials with the delivery of new ships and to have procedures in place for ships delivered after the 1st of July 2002 and after the 1st of January 2011, in compliance with the MSC.1/Circ.1374.

The future goal should be to avoid asbestos containing materials to be used on board ships and in the shipyards, by means of avoiding the use of asbestos at the source.

This “source approach” should be addressed in IMO and within the European Community. E.g. the European Directive concerning the Marine Equipment Directive has no requirements related to asbestos, which could be a first step.

Meanwhile this instruction is the basis for future developments. In some countries shipyards are busy to develop (or are already in place) certified procedures to avoid the use of asbestos containing materials. These certified procedures could be a basis to deviate from this instruction when proven to be reliable. Procedures should be submitted to the NSI for approval.

1 Legislation

Asbestos (= the fibrous silicates actinolite, amosite, anthofyllite, chrysotile, crocidolite and tremolite, and products in which these silicates are processed) containing materials and equipment are not to be used.

Relevant requirements and documents are mentioned underneath:

- The Netherlands legislation (such as Ships Act / Decree 2004, Working Conditions Act / Decree, the Netherlands Decree on asbestos removal ( Asbest verwijderingsbesluit), for asbestos applicable on SOLAS and non SOLAS ships.

- SOLAS Ch. II-1, Regulation 3.5.2 – For all ships, new installation of materials, which contain asbestos, shall be prohibited.

Since 1 July 2002, new installations of asbestos containing materials on board all ships have been allowed only in exceptional cases.

From 1 January 2011, new installations of asbestos containing materials on board ships will, without exception, no longer be allowed.

- MSC.1/Circ.1374, Information on prohibiting the use of asbestos on board ships.

- MSC.1/Circ.1379, Spare parts containing asbestos.

- Resolution MEPC.197(62). Guidelines for the development of the inventory of hazardous materials. (future)

- MSC/Circ.1045, Guidelines for maintenance and monitoring of on-board materials containing asbestos.

- Directive 2009/148/EC on the protection of workers from the risks related to exposure to asbestos at work.

- MSC.1/Circ.1426, Unified interpretation on implementation of SOLAS Ch. II-1, Regulation 3-5.

2 Asbestos investigation

In order to verify the compliance with the rules and regulations under paragraph 1, an Asbestos Investigation should be carried out including sampling and testing/reporting as specified under 3. and 4.

For each commercial ship being built in compliance with the rules of the Netherlands, the shipyard ( suppliers are part of the ship yards responsibility) is responsible for the asbestos investigation. The RO should verify that the asbestos investigation documentation was to their satisfaction and that it is in compliance with this Instruction.

For each commercial ship being built under foreign flag the owner is responsible for the asbestos investigation prior acceptance under the flag of the Netherlands. The RO should verify that the asbestos investigation documentation was to their satisfaction and that it is in compliance with this Instruction.

The asbestos investigation (survey, sampling and analysis) and the validation of asbestos free certificates should be carried out by independent, qualified and licensed companies/persons accredited by a member of ILAC ( International Laboratory Accreditation Cooperation) according to ISO 17025/17020 or equivalent and specific related to asbestos, such as the Netherlands SC-540 certification and having Asbestos surveying and testing in their scope of accreditation, including; testing of the samples, reporting of results. The Asbestos surveying and testing facility may be separate companies.

ISO 17025 covers testing and calibration, including sampling. The survey activity is not covered under ISO 17025.

The survey qualification for the persons carrying out these surveys should be covered by :

The person carrying out the survey works for a company accredited as an inspection body to ISO 17020 or equivalent and /or holds personnel certification for asbestos surveying from a certification body that is accredited to ISO 17024 or equivalent. The person must have suitable / extensive marine experience.

The investigation should be carried out as indicated in the following situations:

2.1 For each commercial ship to be registered under the flag of the Netherlands prior to delivery ( after the 1st 0f January 2011)1 from a shipyard, being either a ship being built in accordance with the rules of the Netherlands, such being surveyed by a RO or a ship being built under foreign flag regulations,

Prior delivery , the Recognized Organization should verify that the ship is delivered asbestos free using the investigation referenced in 2.

Keep in mind that the sampling and this type of validation will always be a limited survey as not all locations/installations onboard can be checked when the vessel is floating already. To reduce this limitation, the asbestos investigations should be carried out during the new building process.

No exemptions for asbestos containing materials should be granted in case the ship is built under Netherlands flag or built under foreign flag and brought under Netherlands flag immediately after delivery. It is recommended that asbestos survey should be carried out maximum three months and minimum one month prior delivery of the vessel. preferably with all systems installed but not filled yet.

Reporting to be available within two weeks after the finalized asbestos survey.

2.2 For each flag-in vessel coming under Netherlands Flag, not falling under paragraph 2.1:

The Recognized Organization should verify for ships built after the 1st of July 2002 compliance with legislation as mentioned under paragraph 1, using the investigation referenced in 2, or verify that during new-building and periodical surveys, equivalent procedures were already followed. For ships built after the 1st of July 2002 and before the 1st of January 2011, according SOLAS II-1/3-5, asbestos is still accepted for :

vanes used in rotary vane compressors and rotary vane vacuum pumps;

watertight joints and linings used for the circulation of fluids when, at high temperature (in excess of 350 °C) or pressure (in excess of 7 x 106 Pa), there is a risk of fire, corrosion or toxicity; and supple and flexible thermal insulation assemblies used for temperatures above 1000 °C.

In case asbestos containing materials (ACM’s) are detected by any party, the MSC.1/Circ.1374 and MSC./Circ. 1379 are applicable and exemptions may be issued by the RO, according paragraph 6. Applicable for ships delivered after the 1st of July 2002 and the 1st of January 2011.

The ship owner should contact the RO for the issue of the exemptions.

Keep in mind that the sampling and this type of validation will always be a limited survey as not all locations/installations onboard can be checked when the vessel is floating already

2.3 For ships delivered after the 1st of July, 2002 but not later than the 1st of January 2011, which already were certified under the Netherlands Flag before the 1st of December 2011:

The ship owner is obliged to make a risk inventory, part of the Risk Inventory and Evaluation2, to identify hazardous situations on board. Asbestos containing materials are part of this inventory. This requirement is applicable for all ships under Netherlands flag.

In case asbestos containing materials are detected, the MSC.1/Circ.1374 and MSC./Circ. 1379 are applicable and exemptions may be issued by the RO, according paragraph 6.

The ship owner should contact the RO for the issue of the exemptions.

In case asbestos containing materials were found on board a ship,, an asbestos survey should also be carried out on board sister ships which are built at the same shipyard during the same period of time and under the same RO, under Netherlands flag.

1

Ships delivered after the 1st of January 2011 and before the entry date ( 1st of December 2011) of the first Instruction are presumed to be examined towards asbestos containing materials in a more stringent way than the verification of an asbestos free declaration or certificate from the yard and suppliers only and more in line with this Instruction.

2

According to the Netherlands working Conditions Act and Decree.

3 Sampling

- Test samples to be taken (randomly) from engine room equipment and systems: piping insulation materials and –connections, gaskets in engine equipment, piping and valves, insulation materials and paneling in accommodation, floors, ceilings and gaskets in deck equipment and piping. Extra attention should be drawn to gaskets in bilge-, ballast-, grey water-, black water-, cooling water-, fire fighting-, oil-, cargo and cargo and exhaust gas systems and their components (e.g. valve contents such as seals and joints).

Extra attention should be paid to exposed components of high risk of both being asbestos and being damaged – ie steam pipe lagging, exposed insulation and lagging in high traffic areas, insulation and lagging in areas likely for high wear or damage, rope seals in accommodation doors which are constantly disturbed and friable.

The components given in the indicative list of MEPC.197(62) should be considered for sampling.

- The amount of samples should be at least to the minimum as here specified however may be increased to the satisfaction of the independent, qualified and licensed asbestos investigation company.

- Samples per vessel to be taken by a certified surveyor from the certified investigation company by his judgment and of all materials suspected of containing asbestos. The RO surveyor may witness the sampling.

As guidance a minimum of 10% of the components per each system, according 3a, where asbestos containing materials are suspected should be sampled , with a maximum amount of 20 samples per each system. If one or more components prove to be Asbestos Containing Materials, a further 10% of other than the originally sampled components/types may be sampled, with a total maximum amount of 50 samples per each system. If these prove to be non-ACM, no further sampling is needed for that system. Otherwise all components should be sampled or to be considered potentially containing asbestos until proven asbestos free.

The components considered “potentially containing asbestos” are part of the Exemption under 6 and should be removed after the expiring of the Exemption, unless sampling indicates that they are asbestos free.

- Sampling points should be clearly marked for location reference. (detail photo of sampling location or by marking sample location.)

Locations should also be indicated in the general arrangement plans of the ship.

4 Testing and reporting

Reporting to the RO and verification of the investigation documentation by the RO should be completed before issue of the Statutory Certificates, for ships mentioned under paragraph 2.1.

For other ships, the testing and reporting is applicable in case asbestos exemptions (see paragraph 6) are issued.

Compliance of onsite taken samples being Asbestos Free is to be determined by:

- Using qualitative analysis method of Polarized Light Microscopy (PLM-optical analysis) as with this method asbestos fibers are either found or not. Asbestos testing laboratory should confirm that with using PLM-optical analysis method they are able to reach the detection limit of </= 0,1% (m/m) of Asbestos in sample. Other methods mentioned in IMO documents may be used. (e.g. ISO/DIS 22262.1). The laboratory test report should state Samples in which no asbestos is detected. The survey report should state the materials and equipment of all asbestos free samples as well.

Non ACM is defined as: Materials proved to have </= 0,1 % of asbestos in the sample. Samples with more than 0,1 % asbestos are considered to be ACM’s.

- The test report should further be in compliance (equivalent to) the Dutch Asbestos Testing Standard, NEN 5896, the Australian standard NOHSC 2018(205), German VDI 3866, or IMO Res. MEPC. 197(62).

5 Removal, cleaning, decontamination and re (tightness) testing

Case A:

Sampling completed and all tested samples proven non-ACM, then after reporting:

Parts, systems and equipment should be retested to verify the sound installation and re-tightness as per RO rules.

Case B:

Sampling completed and tested samples should be proven to be of ACM, then:

- A plan of removal and re-installation should be agreed between the Yard/company and ship owner. The final report containing the feedback of the actions carried out according to the agreed plan should be made available to the RO for recording purposes.

Note: RO’s are not asbestos experts or licensed asbestos companies . RO can only verify that the asbestos listed as found has been listed as removed by the company, and can check the company’s licenses and the timescale and reports, etc.

- Any identified ACM or not proven asbestos free materials should be removed from the vessel. This applies for ships built after the 1st of January 2011. For these ships no exemptions may be issued, except for ships which sailed under foreign flag and flagged in under Netherlands flag.

Ships built after the 1st of July2002 and before the 1st of January2011 and ships which sailed under foreign flag and flagged in under Netherlands flag, delivered after the 1st of January 2011, should have an exemption in case of asbestos containing materials. The asbestos should be removed within a timeframe of maximum 3 years. A timeframe of more than 3 years ( with a maximum of 5 years) may be considered in exceptional cases. These applications should be well founded and first assessed by the classification society before submitted to nsi.

Ships built before the 1st of July 2002; asbestos is allowed when there is no health risk for the persons working in that area due to damaged asbestos containing materials and maintenance work on systems containing asbestos . In these cases repairs and removals are part of the Working Condition Act and to be carried out under the responsibility of the ship owner. ( reference is made to paragraph 2.3)

MSC/Circ.1045 is applicable for those ships.

- Any removal/ re-installation should not be limited to the defected material spots only but is to be extended to include all materials and equipment of the same type, same manufacturer, same system, etc..

- For removal and decontamination of ACM’s and cleaning of the area’s in question, qualified and licensed personnel/companies should be used. In case it can be demonstrated that the threshold limit value of risk class I as defined in Article 4.46 of the Netherlands Working Condition Decree will not be exceeded, the removal of ACM may be carried out by unlicensed personnel/companies. See further under paragraph 8, relevant notes. The shipyard/company is responsible and follow their national requirements throughout the removal process. (responsibility of the relevant country)

In the Netherlands the Decree on asbestos removal and the Netherlands Working Conditions Act and Decree are applicable and only SC 540 ( Stichting Certificatie Asbest Type A survey) and SC530 (removal) certified companies should be used.1

- After removal, decontamination, reinstallation and cleaning a further asbestos closing survey should be carried out, by a qualified and licensed company, by means of a visual inspection for remnants/dust and asbestos airborne fiber and dust monitoring, to verify that no asbestos hazard is present and all ACM is removed according the removal plan. All air monitoring results should be below the control limit of 0.01 fibres/mL. determined via Phase Contrast Microscopy (PCM). This control limit is determined by the “ SER-commissie grenswaarden stoffen op de werkplek” and subject to change. In the Netherlands these closing surveys should be carried out by accredited companies.

- Materials installed to replace ACM’s should be subject to sampling in accordance with the above.

1

SC 540 and SC 530 certified companies are shown on the website : www.ascert.nl

6 Exemptions by RO

Ships delivered after the 1st of July 2002 and already sailing under the Netherlands flag or existing ships coming under the Netherlands flag should use the relevant parts of MSC.1/Circ.1374 and MSC/Circ. 1379, in case ACM has been found ( no exemption is required for the components which are allowed to contain asbestos according SOLAS Ch.II-1,regulation 3.5.2 prior to 1-1-2011).

Under item 13 of the Annex of this Circular, the actions are mentioned in case of contraventions.

The RO should issue a temporary exemption, with a validity of maximal 3 years, according to the procedures mentioned in the agreement between the RO’s and the Netherlands Shipping Inspectorate.

A timeframe of more than 3 years ( with a maximum of 5 years) may be considered in exceptional cases. These applications should be well founded and first assessed by the classification society before submitted to NSI.

The format of the exemption is described in the SOLAS Appendix certificates and should be attached to the Cargo ship Safety Certificate or Cargo ship Safety Construction Certificate or the Passenger Safety Certificate.

The following is needed for an Exemption:

-

Procedures according paragraph 2 of this document are to be followed, resulting in a report according paragraph 4.

-

An action plan, in which is mentioned the summary of materials to be removed, where and when, by whom, submitted by the ship owner to the RO. In the meantime that removal is not possible, regular qualified monitoring of asbestos fibers in the air and a visual inspection for possible deterioration of the ACM may be required by the ship owner and in that case records to be retained on board.

The removal should take place within a time frame of 3 or 5 years from the date when the contravention is found.

-

ISM procedures should identify all possible risks caused by the temporary remaining asbestos, including activities where asbestos may be involved ( opening systems in case of emergency), preferably to be mentioned in an Asbestos Management Plan. Asbestos should be properly marked and made known to crew/contractors.

-

Crew should be informed about the procedures in case of emergency situations when ACM is to be removed. Part of the ISM procedures.

-

Personal protection and special asbestos disposal bags (labeled with asbestos warning signs and specified thickness of plastic) should be onboard. Reference is made to the mandatory risk inventory and evaluation, according to the Netherlands Working Condition Act and Decree. The personal protection should only be used in case of emergency when repairs are necessary and asbestos may be involved.

The personal protection should contain the following items as a minimum:

-

Breathing masks /respirator suited for an environment contaminated with asbestos. (equipped with P3 type filters only).

-

Protective clothing like disposable coveralls.

-

Head covering.

-

Overboots.

-

Gloves.

-

Eye protection.

-

Means to prevent asbestos contamination.

-

RO should track the conditions for and validity of the exemptions during the ISM audits and intermediate safety construction surveys.

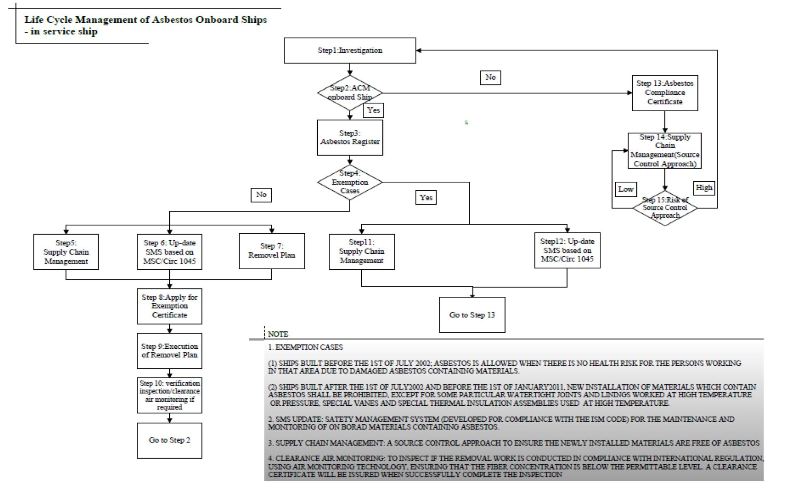

7 Life Cycle Management

Life cycle management may be implemented by the Ship owner to avoid the recontamination with asbestos containing materials during the operation of the ship.

An example has been provided and should be part of the ISM system or maintenance system and RI&E if ISM is not required.

8 Relevant NOTES

- On board ships built before the 1st of July 2002, asbestos is still allowed in the existing construction.

It is the responsibility of the ship owner to warrant that no ACM’s are damaged and will not create a hazardous environment for the crew and persons visiting the ship or when working on its systems. This requirement is according the Netherlands Working Condition Act and Decree and should be part of the Risk Inventory and Evaluation.

- Document MSC/Circ.1045 may be used as a guideline for maintenance of onboard materials containing asbestos.

- Reference is made to the Hong Kong International Convention for the safe and environmentally sound recycling of ships 2009, not yet entered into force, requiring that ships shall have on board an inventory of hazardous materials ( e.g. asbestos), in line with Resolution MEPC.197(62), 2011; Guidelines for the development of the inventory of hazardous materials.

- In general, RO’s may recognize organizations for the sampling and analysis, according the requirements developed within IACS or the RO itself.

- Asbestos investigation reports are to make clear reference to these asbestos instructions.

Reports based on SC 540 type A may be used, when the investigation followed this instruction and clear reference has been made in the report to these asbestos instructions.

- In case of asbestos investigations/reports are available before the 1st of December 2011, the three years timeframe will be calculated from the 1st of December 2011.

- When asbestos containing materials are involved meeting the risc class I, according the Netherlands Working Condition Decree conditions, these materials may be removed by the crew under specified conditions.

This concerns in principle gaskets. The removal of gaskets may be categorised under two risc classes (1 or 2). The risc class is determined by means of SMArt (Stoffen Manager Asbest risico toepassingen, see www.asbestinfo.nl). A risc class 1 removal is only possible when the gasket is loose or can be removed without damage. These operations may be carried out by the crew, when properly trained, provided with sufficient personel protection and under conditions that asbestos particulars in the air are avoided.

Situations falling under risc class 2 are under discussion. For risc class 2 situations, materials may not be removed by the crew.

A risk class 2 removal is applicable in all cases when gaskets cannot be removed without damage for instance when gaskets are glued.

- Under 5.d is indicated that In case it can be demonstrated that the threshold limit value of risk class I as defined in Article 4.46 of the Netherlands Working Condition Decree will not be exceeded, the removal of ACM may be carried out by unlicensed personnel/companies. Further elaboration is required on the way this should be demonstrated.

- Permanent exemption shall not be granted, even in case that asbestos containing material cannot reasonably be safely removed and the asbestos containing material does not generate airborne asbestos fibers. Within IMO requirements ( SOLAS) and MSC./Circulars, no possibilities are given.

The Netherlands will seek support in IMO for permanent exemptions in case that asbestos containing material cannot reasonably be removed and the asbestos containing material does not generate airborne asbestos fibers.

- Ships changing into the Netherlands flag, where the asbestos investigation is required according paragraph 2.2, may finalize sampling, analysis and reporting within three months after the date of entry under the Netherlands flag.

Annex 1 - List of definitions

Systems: The components given in the indicative list of MEPC.197(62)should be considered.

Further more:

piping insulation materials and –connections, gaskets in engine equipment, piping and valves, insulation materials and paneling in accommodation, floors, ceilings and gaskets in deck equipment and piping. Extra attention should be drawn to gaskets in bilge-, ballast-, gray water-, black water-, cooling water-, fire fighting-, oil-, cargo and cargo and exhaust gas systems and their components.

SOLAS and non SOLAS: All ships (including those without propulsion) falling under the Netherlands Ships Act / Decree 2004.

New-installations: As defined in the MSC circ. 1379.

Non ACM is defined as: Materials proved to have < /= 0,1 % of asbestos in the sample. Samples with more than 0,1 % asbestos are considered to be ACM’s.

SC-530: The Asbestos Removal Standard in The Netherlands to which asbestos removal companies are certified. Only sc-530 certified companies are allowed to remove acm in the netherlands.SC-540: The Asbestos Survey standard in the netherlands to which asbestos surveying companies are certified. Only SC-540 certified companies are allowed to issue Type A asbestos survey reports.