For the purpose of the Code the following definitions apply. Additional definitions are given

elsewhere in the Code.

1.4.1 Accommodation spaces: Cabins, offices (for carrying out ship's business), hospitals, mess rooms,

recreation rooms (such as lounges, smoke rooms, cinemas, libraries and hobbies and games rooms) and

open recreation areas to be used by seafarers.

1.4.2 Auxiliary machinery: Machinery other than main propelling machinery that is in service when the

ship is in normal service, e.g. auxiliary diesel engines, turbo-generators, hydraulic motors and pumps,

compressors, boiler ventilation fans, gear pumps.

1.4.3 A-weighted sound pressure level or noise level: The quantity measured by a sound level meter

in which the frequency response is weighted according to the A-weighting curve (see IEC publication

651).

1.4.4 Continuously manned spaces: Spaces in which the continuous or prolonged presence of seafarers

is necessary for normal operational periods.

1.4.5 Crane barge: A vessel with permanently installed cranes designed principally for lifting operations.

1.4.6 Duty stations: Those spaces in which the main navigating equipment, the ship's radio or the

emergency source of power are located or where the fire recording or fire control equipment is

centralized and also those spaces used for galleys, main pantries, stores (except isolated pantries and

lockers),mail and specie rooms, workshops other than those forming part of the machinery spaces and

similar such spaces.

1.4.7 Dynamically supported craft: A craft which is operable on or above water and which has

characteristics different from those of conventional displacement ships. Within the aforementioned

generality, a craft which complies with either of the following characteristics:

.1 the weight, or a significant part thereof, is balanced in one mode of operation by other than

hydrostatic forces;

.2 the craft is able to operate at speeds such that the function v/√gL is equal to or greater than 0.9,

where "v" is the maximum speed, "L" is the water-line length and "g" is the acceleration due to gravity, all in consistent units.

1.4.8 Ear protector: A device worn to reduce the level of noise heard by the wearer.

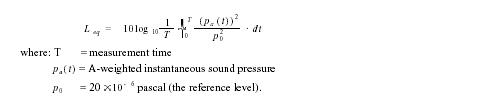

1.4.9 Effective sound level L

ef (x)(H ) : A notional continuous sound level which is calculated from the

various A-weighted sound levels and duration at these levels with an XdB exchange rate. The exchange

rate is the number of dB decrease in noise level which would allow doubling of exposure time. Lef(3)(H) is

equal to Leq(H). In instances of fluctuating noise and intermittent exposures 5 dB is often used for X. "H"

represents the time period concerned expressed in hours.

1.4.10 Equivalent continuous sound level Leq(H): A notional level which would in the course of a given

time period (H) cause the same A-weighted sound energy to be received as that due to the actual sound

over the period. "H" represents the time period concerned expressed in hours.

1.4.11 Fishing vessel: A vessel used commercially for catching fish, whales, seals, walrus or other living

resources of the sea.

1.4.12 Fluctuating noise: Noise which is varying in level rising and falling. For the purpose of this Code

it may be taken to mean fluctuations in excess of the steady noise as defined in 1.4.31 and excludes

impulse noise as defined in 1.4.14.

1.4.13 Hearing loss: Hearing loss is evaluated in relation to a reference auditory threshold defined

conventionally in ISO Standard 389 (1975). The hearing loss corresponds to the difference between the

auditory threshold of the subject being examined and the reference auditory threshold. ISO Standard

1999 (1975)* takes an average loss of 25 dB calculated at frequencies 500, 1,000 and 2,000 Hz.

1.4.14 Impulse noise: Noise of less than one second's duration which occurs as an isolated event, or as

one of a series of events with a repetition rate of less than 15 times per second.

1.4.15 Integrating sound level meter: A sound level meter designed or adapted to measure the level

of the mean squared time averaged A-weighted sound pressure.

1.4.16 ISO noise rating (NR) number: The number found by plotting the octave band spectrum on the

NR curves given in ISO Standard R 1996-1967 and selecting the highest noise rating curve to which the

spectrum is tangent.

1.4.17 Machinery spaces: All spaces containing propulsion machinery, boilers, oil fuel units, steam

and internal combustion engines, generators and major electrical machinery, oil filling stations,

refrigerating, stabilizing, ventilation and air-conditioning machinery and similar spaces, and trunks

to such spaces.

1.4.18 Mobile offshore drilling unit: A vessel capable of engaging in drilling operations for the

exploration for, or exploitation of, resources beneath the sea-bed, such as liquid or gaseous hydrocarbons, sulphur or salt.

1.4.19 Navigating bridge wings: Those parts of the ship's navigating bridge extending towards the

ship's sides.

1.4.20 Noise: For the purpose of the Code all sound which can result in hearing impairment, or which

can be harmful to health or be otherwise dangerous.

1.4.21 Noise induced hearing loss: A hearing loss, originating in the nerve cells within the cochlea,

attributable to the effects of sound.

1.4.22 Noise level: See A-weighted sound pressure level (1.4.3).

1.4.23 Normal service shaft speed: The shaft speed specified for the ship's acceptance on initial

delivery, or after being modified, as applicable.

1.4.24 Occasional exposures: Those exposures typically occurring once per week, or less frequently.

1.4.25 Passenger: Any person on board other than the master and members of the crew or other

persons employed or engaged in any capacity on board a ship on the business of that ship.

1.4.26 Pipe-laying barge: A vessel specifically constructed for, or used in conjunction with, operations

associated with the laying of submarine pipelines.

1.4.27 Port condition: The condition in which all machinery solely required for propulsion is

stopped.

1.4.28 Potentially hazardous noise levels: Those levels at and above which persons exposed to them

without protection are at risk of sustaining a noise induced hearing loss.

1.4.29 Sound: Energy that is transmitted by pressure waves in air or other materials and is the objective

cause of the sensation of hearing.

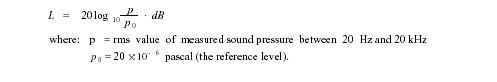

1.4.30 Sound pressure level: A measure of sound level, L, on a logarithmic scale given by:

1.4.31 Steady noise: A sound where the level fluctuates through a total range of less than 5 dB(A) as

measured on the "slow" response of a sound level meter in one minute.

1.4.32 Voyages of short duration: Voyages where the ship is not generally underway for periods long

enough for seafarers to require sleep, or long off-duty periods, during the voyages.